APF For Coagulation and Flocculation

Flocculation is an essential part of the filtration process. The addition of a positive charge usually in the form aluminium ions is essential to ensure minute particles are bind together and therefore filtered out by the filter media. APF is one of the newest and most innovative flocculants on the UK market and John Monaghan an STA Pool Plant tutor has kindly provided the following article on APF.

APF is a multi-spectrum coagulant and flocculant which comprises of a combination of electrolytes and polyelectrolytes in order to remove as much as possible from solution and flocculate all particles from suspension.

The process by which APF removes chemicals from solution is called coagulation which is performed by the electrolyte components of the product. Coagulation is a bit like taking sugar out of tea and returning it to granular form which is then removed by the AFM active filter media. The coagulated particles then grow in size by a flocculation reaction. The solids are retained by the filter and removed during the back-wash.

Coagulation only works when APF is dosed into a ZPM (zeta potential mixer), flocculation and the growth of the flocculated particle happens slowly. The objective is to grow the particle as large as possible before the water reaches the AFM filter bed. It is therefore important to use filters that are in compliance to the German DIN standard because they provide a large head space above the filter bed. The head space gives extra time for the flocculated particle to grow, and the larger the particle the easier it is to remove from the water.

Application Rate

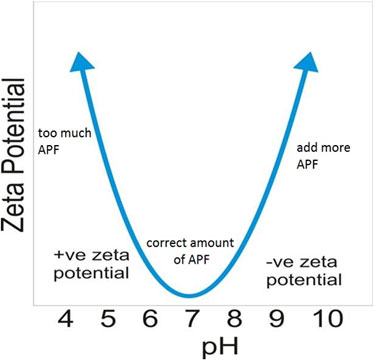

The APF application rate must satisfy the coagulation and flocculation demand of the water, it is important to add sufficient APF to satisfy this demand, but not too much or it will have a negative effect. The optimum dose rate is calculated by measuring the aluminium content of the water. Aluminium is one of the components of APF, if it can be measure after the filter then the APF demand will have been satisfied. As a starting point, the application level should be equivalent to 1 ml of APF per 1 m3 of water passed through the AFM filter bed.

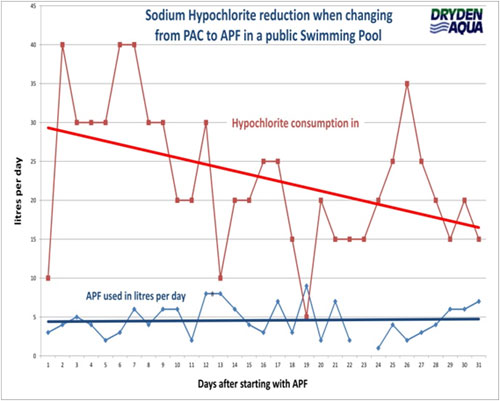

Getting the levels correct we will save considerable money on chlorine and guarantee the removal of cryptosporidium, resulting in a sparkling water and 25m visibility through the pool.

Water Quality

APF contains 10 different components including polyaluminium chloride, APF also contains coagulant as well as phosphate precipitating agents so it performs many functions, this is why it is callled a multi-spectrum activated flocculant. In order for APF to work best, the pH should be between 7.0 and 7.4, calcium hardness should be above 100mg/l and alkalinity between 60mg/l and 100 mg/l.

After the ZPM the passage of the water should be as gentle as possible to minimize turbulence and avoid break-up of the flocculated particle. Multi-port valves should be avoided because they cause too much turbulence.

Points to Remember

Do not add APF before your main circulation pump because the APF will hydrolyse and the the long chain molecules will be broken up by the pump. Even if the injection point is right on top of the pump the APF will react with the water, and then the long chain molecules will be broken up by the pump. Flocculation only happens once so the conditions need to be right for the reactions to progress.

You would not add chlorine or pH correction chemicals without testing them. This is exactly the same with flocculation, you should be testing on a daily or at least a weekly basis for aluminum and turbidity. APF should be added until aluminum is detected in the product water. The turbidity should then fall to zero, or less than 0.05 ntu. If the turbidity does not fall then the filter is not working properly, the most likely explanation is worm-hole channeling of water through the filter bed. This is quite common when using sand, but it does not happen with AFM when used in a good quality filter. The aluminium should always be below 0.2 mg/l, if APF is over dosed then the opposite can happen and the turbidity may increase, so it is important too get the application rate right and the Zeta potential at the lowest possible level.

The application rate of APF is a function of the pool size and water flow rates, but fundamentally the pumping rate should be in relation to the bather loading. As a starting point for public pools add 1 ml of APF for every 1 m3 of water passed through the filter. By way of example if the water flow rate is 120 m3/hr then the dosage rate would be 120ml/hr, but if it is a quiet pool then you may only need 0.5ml of APF per 1 m3/hr.

Some Key Points and a Video

- APF Flocculation video

- When flocculation is optimised, i.e. the aluminum levels and turbidity are correct, you will form a solid floc of metal hydroxide – ACO helps to stablize the floc by forming an aluminosilicate

- Coagulation and flocculation under controlled conditions will remove suspended and dissolved contaminants by mechanisms of charge neutralization, absorption and entrapment within the filter

- The factors which influence the efficiency of how the product works are based on dosage rates and pH of the pool – the required dose and pH can be determined by simple testing

- There is no point using coagulant/flocculant if you are filtering over 30 m/hr

- A non-return valve must be used at the injection point on the end of the hose

- Avoid the use of any chemicals containing sulphates

- Alkalinity 60 to 100 mg/l, hardness above 100mg/l as calcium, pH 7.0 to 7.4.

- Categories

- Pool Plant